Inductors

& transformers

solutions provider

and manufacturer

Innovation, Breakthrough, Inclusive, Recognition

Inductors

& transformers

solutions provider

and manufacturer

Innovation, Breakthrough, Inclusive, Recognition

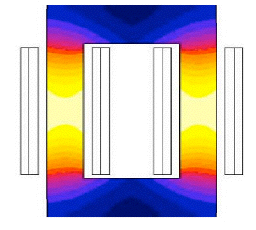

Thermal field in E magnetic core is not uniform. Winding covering only 40-60% of magnetic core area (LIMB), creating hot spots and reducing cooling efficiency.

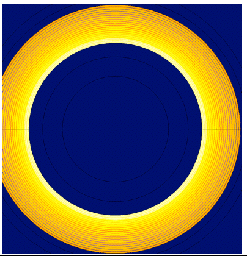

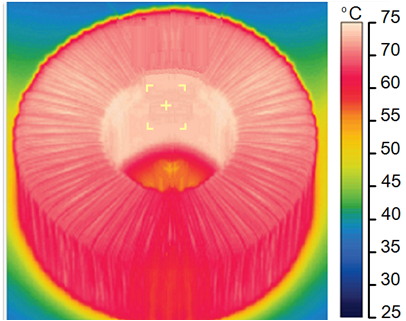

Toroidal core is uniform, without hot spot.

Toroidal core surface completely surrounded

by coil + smaller coil thickness = improved cooling efficiency.

Best cooling efficiency is achieved with toroidal shape, because 100% of the magnetic core is completely surrounded by winding of material of high thermal conductivity like copper or aluminium wire.

| Thermal Conductivity | |

| Copper | 394 |

| Aluminium | 209 |

| Iron powder core | 2-6 |

| Polyimide tape | 0,12 |

| Air | 0,025 |

Please contact us for any free request and technical advice to review feasibility of toroidal winding technology for your inductors and transformers in your applications, or fill your RFQ on our online projects platform here