Inductors

& transformers

solutions provider

and manufacturer

Innovation, Breakthrough, Inclusive, Recognition

Inductors

& transformers

solutions provider

and manufacturer

Innovation, Breakthrough, Inclusive, Recognition

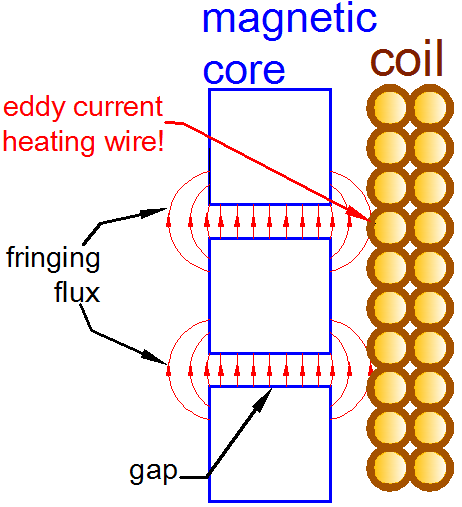

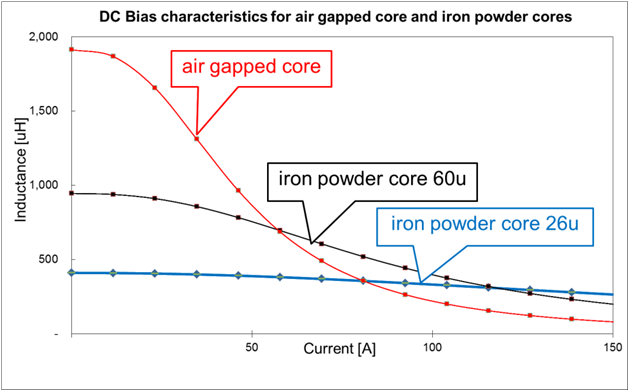

Cut cores technology creates fringing flux and eddy current in coil and magnetic core. Inductor reaches sharp saturation level because of the discrete gap structure, requiring a lot of headroom in the design.

Discrete air gap structure in magnetic cores increase significantly the acoustic noise.

Fringing flux in E magnetic core

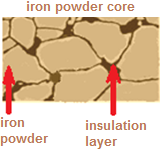

Iron powder core with distributed air gap reduces fringing flux phenomena.

Iron powder core

The variety of iron powder materials allows for optimized magnetic and electrical properties of toroidal inductors:

Toroidal iron powder cores are available in a continuous wider range of characteristics and become more and more competitive.

DC bias characterisitics for different core

Please contact us for any free request and technical advice to review feasibility of toroidal winding technology for your inductors and transformers in your applications, or fill your RFQ on our online projects platform here.